Selecting the correct flux core welding wire is one of the most important decisions in structural welding. The choice influences weld quality, mechanical strength, penetration, efficiency and service life of the welded structure. Structural steelwork often involves heavy loading, vibration and dynamic stresses. Using the right consumables ensures strong joints and reduces the risk of rework or premature failure. Structural welding differs from light fabrication welding in that it requires deep penetration, reliable weld metal properties and consistent deposition even in challenging environments.

What Is Flux Core Welding Wire?

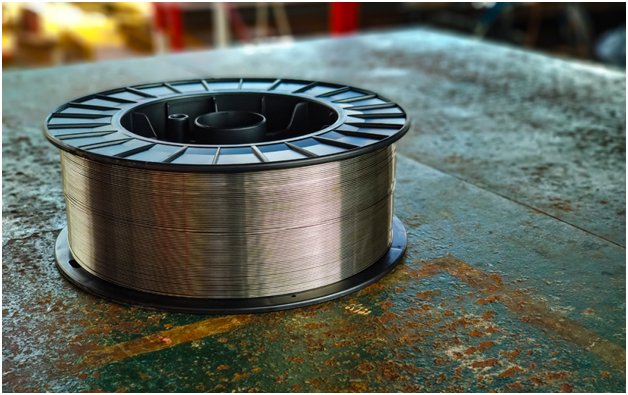

Flux core welding wire (FCAW) is a tubular wire that contains a fluxing agent within its hollow core. During welding, the flux generates a protective atmosphere around the weld pool, shielding it from contamination. This makes flux core welding particularly suited to situations where external gas shielding is impractical, such as outdoors or on large structural steelwork.

Flux-cored wires are typically used with direct-current equipment and are valued for their high deposition rate and deep-penetration characteristics. In structural applications, they can rival or exceed the performance of solid wire when properly selected and applied.

Self‑Shielded vs Gas‑Shielded Flux Core Wire

Flux core welding wires are available in two main types, each suited to specific welding conditions. Understanding the differences between these types helps welders select the right wire for the project and achieve high-quality, consistent welds.

| Type of Flux Core Wire | Description | Advantages |

| Self‑Shielded | Does not require an external shielding gas; the flux inside generates protective gases. Ideal for outdoor sites and heavy fabrication. | – No need for gas cylinders – Performs well in draughty/outdoor conditions – Faster setup and greater mobility |

| Gas‑Shielded | Requires an external shielding gas (CO₂ or argon-CO₂ mixture). Provides additional protection and cleaner welds. | – Cleaner weld appearance – Lower slag content – Better bead control and profile |

Choosing the appropriate type depends on the working environment and the joint requirements. Self‑shielded wires are generally preferred for outdoor or high-wind conditions, while gas‑shielded wires are better suited to controlled indoor environments where weld appearance and bead quality are priorities. Using reliable flux-core welding wires, such as those from Superon Technik, ensures consistent arc stability, smooth bead formation and dependable performance in both workshop and field applications.

Key Factors to Consider

When selecting a flux core welding wire for structural work, several practical factors should be evaluated:

Base Metal and Joint Design

The composition and thickness of the base metal strongly influence the choice of wire. Structural steels vary in carbon content and alloying elements. Ensure the flux core wire has compatible metallurgical properties.

For instances involving stainless or duplex materials within a structure, you might also consider an ss welding filler wire if stainless sections require joining. Solid stainless filler wires are designed for corrosion resistance and ductility in stainless steel, whereas flux core wires are optimised for carbon and low‑alloy steels.

Mechanical Strength Requirements

Structural applications often demand specific tensile and yield strengths. Review the mechanical properties of the flux-core wire against the design specifications. Some wires are formulated to achieve high strength and toughness, making them suitable for load‑bearing joints.

Consult relevant standards (e.g., AWS, ISO) to verify that the selected wire meets the minimum strength requirements for your project.

Welding Position and Accessibility

Flux-cored wires are classified for different welding positions. If vertical, overhead or tight‑access welding is required, choose a wire rated for positional welding.

Wires with superior fluid control and stable arc behaviour help maintain quality in challenging orientations. Mis‑matched wire selection can lead to poor bead shape, excessive spatter and inconsistent penetration.

Environmental and Jobsite Conditions

Environmental factors such as wind, humidity and temperature changes affect shielding gas and weld stability. Self‑shielded flux-core wires are generally more tolerant of outdoor conditions, whereas gas‑shielded wires perform in controlled indoor environments.

For field welding on large structures, self‑shielded wires reduce reliance on shielding cylinders and simplify setup.

Deposition Rate and Efficiency

In large-scale structural projects, deposition rate and welding speed are critical to productivity. Flux-cored wires often offer higher deposition rates than solid wires, reducing welding time. Pair this with appropriate current settings to achieve efficient, deep-penetration welding.

However, higher deposition rates may produce more spatter. Balancing speed with cleanliness and quality is essential.

Avoiding Common Selection Mistakes

Even experienced welders can make errors in consumable selection. Some common pitfalls include:

- Choosing a flux core wire that is not compatible with the base metal’s composition

- Overlooking the need for all‑position welding capability

- Using gas‑shielded wire outdoors without adequate shielding

- Relying on a wire that does not meet the project’s mechanical standards

- Assuming stainless welding wires (like ss welding filler wire) can substitute for flux core wire in carbon steel applications

Avoiding these mistakes helps maintain structural integrity and reduces costly rework.

Conclusion

Choosing the right flux-core welding wire for structural welding is crucial to achieving strong, durable, high‑quality joints. Understanding the differences between self‑shielded and gas‑shielded wires, evaluating base metal and environmental conditions and aligning selections with mechanical requirements are central to success.

Whether working on heavy fabrication or routine maintenance, using the correct welding consumables improves performance and reduces downtime. In cases where stainless steel components are involved, selecting an appropriate ss welding filler wire ensures compatibility and long‑term service life. Good consumable choice, combined with proper technique and preparation, supports reliable structural welding outcomes and workplace efficiency.